2030 Sustainability Action Plan

Take a look at our updated plan for 2024-2027 as part of the AIA's 2030 Commitment Program.

View Post

The 2025 NESEA (Northeast Sustainable Energy Association) conference, held in Boston last month, was inspiring in its breadth and depth of information, with folks from all over the country sharing insights into making buildings more energy efficient. This year’s timely conference theme, “Build the Movement,” sought to motivate and supercharge our collective commitment with action and urgency. The A/E/C industry has the knowledge and ability to meet our necessary climate goals and now, we need to expand the conversation to include all parties within the building community so that we move forward together.

We’ve compiled a few pertinent takeaways that we’re excited to implement and we encourage you to consider how you can participate in the solution. A huge shout-out to NESEA and all of their supporters!

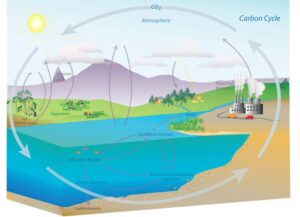

One of the growing trends within the green building movement is to take a step back and look at the larger systems in which we work, which are fundamental to everything we do. We work with material systems, carbon systems, social and economic systems. How we interact with these systems creates feedback loops that lead to their long-term sustainability or failure.

The materials going into our buildings are a limited resource. Accordingly, that means we need to use materials efficiently, utilize them as long as possible, and then responsibly return them to the system so they can complete the material cycle and be used again. This concept is also tied to the carbon cycle, where bio-based materials can absorb and sequester carbon while in use, and then return their carbon and nutrients to the ground to decompose and be reabsorbed into new bio-based materials.

Some examples of this include using agricultural byproducts like straw and hemp to create insulation, engineered lumber, or composite panels. Some non-bio-based materials like steel and concrete are also completing material cycles with close to 100% recycling rates. Some are working on ways to reuse these structural elements through disassembly, which avoids the additional energy used in reprocessing the steel. A tremendously effective reuse of materials is the reuse of existing buildings, which is detailed in the Renovation Reinvented section.

Carbon cycles are more complicated, but there’s great research being done to understand how carbon is emitted and absorbed into soil. Massachusetts Healthy Soils Action Plan provides an in-depth analysis of the soils and biomes that hold the most soil organic carbon and how those soils are distributed across the state. For example, Massachusetts’ wetlands hold approximately 50% of the state’s soil organic carbon even though they account for only 12% of the land. Unfortunately, construction operations often release most of the soil carbon when the ground is disturbed, sometimes exceeding the embodied carbon of the building itself. With proper site design and a soil preservation & management plan, those impacts can be reduced by as much as 75%. This information is an opportunity for the construction industry to improve upon current practices.

At a larger scale, these efforts occur within our social and economic systems. The state of Maine, for example, has committed to building 84,000 new housing units by 2030 and some manufacturers presented avenues to meeting that target by specifying bio-based prefabricated panels to increase the speed and efficiency of construction. Amazingly, if production efficiency is maximized, the housing units could be built at a considerably lower cost than the state average.

This efficiency also requires a shift in our social systems, changing from the current standard of single-family homes at one house/acre to denser row houses or low-rise apartment buildings. This is achievable without sacrificing community open space and it leaves more of Maine’s forests and wilderness alone to support the current carbon cycle and forestry industry. Further, to scale production to meet Maine’s housing commitments, they estimate a need for about 70 new production facilities, creating opportunity for new local business and new green jobs to grow Maine’s economy. Expanding this approach of building with local materials and supporting local businesses to address the US’s nationwide housing shortage of approximately 4.5 million units could have significant social and economic benefits across the country.

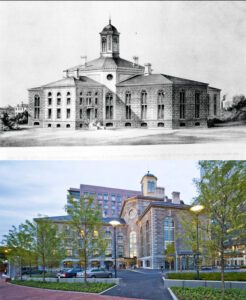

One of the hottest topics circulating in the building industry is an old one; how to re-use an existing building and transform it for the next generation. Re-use of existing structures may be the single largest tool we have to reduce our embodied carbon impacts. Adapting existing structures to new uses has precedent, whether changing use of a decommissioned prison into a hotel, or converting an old foundry into a bustling community arts hub, for example. At NESEA we gained insight into achievable measures for modernizing existing structures.

Thankfully, we don’t need to adopt 1970s energy-crisis approaches, such as replacing all windows with much smaller openings. There are, however, a few key building components to consider when bringing a building into the modern era:

In larger projects, there are typically three routes designers investigate for the envelope:

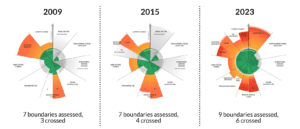

The future for our planet looks too warm. The “Decarb Do No Harm” panel at the NESEA BuildingEnergy session rekindled the imperative to act immediately! Humanity is pushing the boundaries, quite literally, of what the earth can sustain for us. The Stockholm Resilience Centre has published the idea of Nine Planetary Boundaries, or sustainable environmental thresholds, six of which have already been crossed since 2023. With 40% of the world’s energy consumed by buildings, designers must consider what we can do to cool it—our future world.

The future of building design, fortunately, is rapidly moving away from global warming fossil fuels as architects, engineers, and developers focus on electrification and decarbonization strategies tailored to a variety of building types and retrofit conditions. Driven by local policies like Boston’s BERDO (Building Emissions Reduction And Disclosure Ordinance), New York City’s Local Law 97, and supported by financial incentives, projects are prioritizing energy reductions through envelope and HVAC upgrades, and decarbonization by going all-electric.

Passive House standards and energy modeling tools are becoming common practice both to comply with current energy codes (Massachusetts’ Stretch Energy code being one of the most rigorous in the country) and to realize system cost savings. Affordable housing and historic retrofit projects have benefited financially from diving into decarbonization and electrification efforts. Successful examples of this trend show that deep energy cuts—such as 73% Energy Use Intensity (EUI) reductions—are possible and economically viable. Electrification furthers our environmental objectives as architects and designers.

When decarbonization is baked into the design team’s objectives as early as possible, it becomes the ethos of the project, rather than an afterthought. Building systems get integrated into the design strategy for the building as a whole and coordinated early between architects and general contractors to address envelope detailing, thermal bridging, and system sizing. One NESEA conference session focused on a small municipal garage that used ground-source heat pumps as part of an overall electrified building strategy, as well as a peak demand control system, an apparent secret (shhhh, don’t tell) to controlling costs in an all-electric building. While small, the project demonstrated that committing to electrification and collaborating early can have major impact a larger scale.

It’s important to note that electrification as a true pathway to decarbonization depends heavily on the readiness and transformation of the electricity grid to renewables. With the studied future fall-off of utility companies’ fossil fuel use, buildings that are fully electric now will be better positioned for future resilience and compliance. Gas and oil will become more costly for heating our buildings as supply dwindles and demand decreases, according to reports such as “New Construction and the Future of Gas in Massachusetts,” from Groundwork Data commissioned by ZeroCarbonMA. While important, it is not enough to only design better buildings or retrofits. The Massachusetts 2050 Decarbonization Roadmap indicates a systems engineering approach to achieving net-zero greenhouse gas emissions by 2050, including a focus on renewable energy supply such as solar and wind.

Whether you’ve been on this journey for decades or this article is your first step in creating a more sustainable future, everyone plays a critical part for continuing to build this movement. Consider your role in the built environment and ask yourself some questions: Are you part of the building supply chain as a designer, manufacturer, builder, developer, or owner? Do you affect the built environment through education, government, finance, analytics, or another related field? By examining these questions, you and your colleagues can establish goals for how your work can support change.

Start with the numerous networks and organizations linked below, to find resources and further ways to support the power of collective action.

Bio-based Materials Collective

Take a look at our updated plan for 2024-2027 as part of the AIA's 2030 Commitment Program.

View PostEnvironment+Energy Leader - December 19, 2024

Principal Adam Mitchell shares his expertise on how to design innovative, immersive aquarium experiences that also educate visitors on topics of sustainability and ocean conservation.

View PostEnvironment+Energy Leader - October 25, 2024

Maddie Burns talks enhancing urban biodiversity through native landscaping improves climate resilience, sustainability, and environmental justice in cities with Environment+Energy Leader.

View Post